Copper and Aluminium Foil Winder Copper Foil Winding Machine TIG Welding

Description of copper foil winding machine BRJ1400-2

Cast resin transformer copper foil winding machine BRJ1400-2 is one of conductor film winder. This kind of foil winding machine can be used to wind foil coils. The foil coils is for making cast resin transformers and other similar products. With two foil decolers and two insulation decoilers, the kind of copper foil winding machine can handle one or two layers of copper film or aluminium foil and one or two layers of insulation paper. One TIG welding unit is for welding the conductor foil with the bus bar together. Moreover, the copper foil winding machine can be customized as requested, such as the foil decoiler expanding range. Usually, the foil decoiler expanding range is from 420mm to 520mm, which is suitable for the conductor foil with inner diameter 500mm. The control system is based on PLC.

Main Components of copper foil winding machine BRJ1400-2

1. Main frame, iron welded frame is very strong and stable

2. Winding unit, with 22kw motor, providing high torque

3. Foil decoiler, two foil decoiler suitable for conductor foil with inner diameter 500mm

4. Insulation decoiler, two insulation decoiler for placing insulation paer with ID 76mm OD 400mm

5. End-filling strip feeder, eight holder for end insulation filler

6. Cleaning system, two sets

7. Cutting system, one set

8. Foil deburring system, two sets.

Technical Parameters of copper foil winding machine BRJ1400-2

Typical standard specifications of copper foil winding machine BRJ1400-2 are shown below, however, these can be easily modified as requested.

| Max. Foil Width: |

1,400mm |

| Max. Finished Coil OD.: |

1,000mm |

| Finished Coil Shape: |

oval, round and rectangular,etc. |

| Conductor Foil Material: |

Copper or Aluminum |

| Conductor Material OD.: |

Ø1,000mm |

| Conductor Material ID.: |

Ø500mm |

| Foil Decoiler Number: |

2 pcs |

| Foil Decoiler Diameter: |

adjustable range Ø400 ~ 520mm |

| Max. Coil Weight: |

2,000KG |

| Welding Mode: |

TIG |

| Cutting Mode: |

Rolling shear |

| Insulation Decoiler Number: |

2 pcs |

| End-filling Strip Feeder: |

8 pcs |

| Edge Alignment System: |

Photoelectric sensing |

| Rectification Precision: |

±0.5mm |

| Electronic Control System: |

PLC |

| User Interface: |

10inch (254mm) touch screen |

| Counting Turns Range: |

0 ~ 9999.9 |

| Total Weight: |

8000Kg |

| Dimension(L x W x H): |

5800 x 2850 x 2500mm |

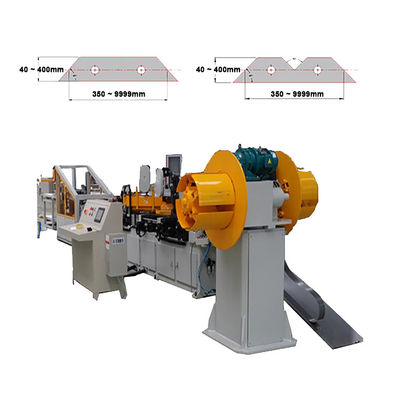

Fig 1: Copper foil winding machine BRJ1600-2's front view

Fig 2: Copper foil winding machine BRJ1600-2's insulation decoiler

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!