Transformer foil winding machines are specialized equipment for manufacturing power transformers and other similar products. Unlike traditional wire wound coils, these machines handle thin, wide sheets of conductive foil, typically aluminum or copper, to create the transformer's windings. This process is crucial for producing compact, high performance transformers used in power supplies, industrial equipment, and renewable energy systems.

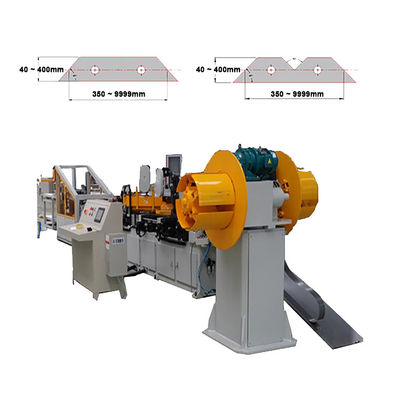

The core working principle of a foil winding machine involves precisely unwinding the metal foil from a large spool and feeding it through a series of guiding and tensioning rollers. These rollers ensure the foil is perfectly flat and under consistent tension, which is vital for creating a uniform and stable winding.

As the central winding mandrel rotates, the machine layers the foil onto the transformer core. A key component working in sync is the edge control system, which uses sensors to keep the foil perfectly aligned with each rotation, preventing gaps or overlaps. Simultaneously, an insulation material, often a thin plastic film, is fed from a separate spool and laid between each layer of foil. This automated interlayer insulation is critical for preventing short circuits and ensuring the transformer's electrical integrity.

Modern foil winding machines are controlled by sophisticated CNC systems, allowing operators to program the exact number of layers, tension settings, and winding speed. This automation guarantees repeatable precision, resulting in transformers with excellent thermal performance, high short circuit strength, and minimal energy loss.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!