The energy sector is constantly evolving, driven by changes in grid modernization, renewable energy integration, and new material science. A manufacturer's capital equipment must be flexible enough to handle not just today's standard products, but also the complex, custom designs of tomorrow. Investing in our custom-built Transformer Winding Machines is an assurance of future-proofing, providing a flexible platform that can adapt to future requirements, unlike rigid, off-the-shelf equipment.

Our approach begins with a Modular Design Architecture. Both our Foil and Coil Winding Machines are built around a robust, scalable frame that can accommodate a wide range of optional add-ons. For instance, a manufacturer may start with standard copper wire winding but later need to integrate specialized features like automatic strand transposition for large power transformers. Our modular design allows for the seamless, field-level addition of these complex components—such as automated brazing stations, multiple wire payoffs, or vacuum impregnation modules—without requiring a costly full machine replacement.

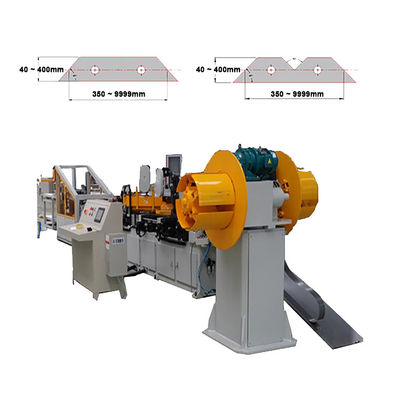

Furthermore, we offer deep customization based on your largest product dimensions and material handling needs. If you specialize in extremely large, high-voltage coils, we can customize the machine's payload capacity, increase the spindle torque, and extend the traverse length and diameter capacity, ensuring the equipment is specifically tailored to your largest potential future product. This eliminates the constant threat of outgrowing your capital equipment as your product line evolves.

Crucially, the software that controls our machines is designed for maximum programming flexibility. Our control systems use open architecture principles, making it easy to integrate with your existing ERP or MES systems for data exchange. This allows for over-the-air software updates to introduce new winding recipes, process improvements, or diagnostic features as they are developed. This software adaptability, combined with the modular hardware, means your investment remains relevant and highly productive for decades. When you choose our custom winding solution, you are not just buying a machine; you are securing a scalable, adaptable manufacturing platform that will continuously meet the demands of the transformer industry's future.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!