The heart of any transformer lies in its coils, meticulously wound to transfer electrical energy with minimal loss. This intricate process is expertly handled by a Transformer Coil Winding Machine. But what is the function of this machine, and how does it guarantee the electrical efficiency that is so crucial for power distribution and electronic devices?

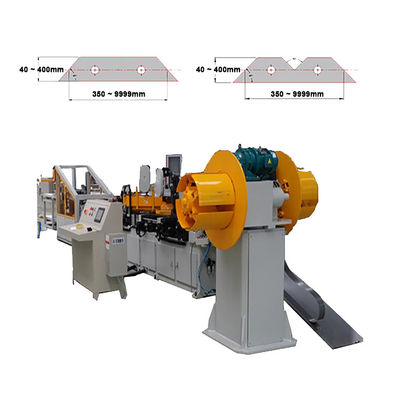

A Transformer Coil Winding Machine is a specialized piece of equipment designed to precisely wind copper or aluminum wire (or sometimes foil, as with a Copper Foil Winding Machine) into various coil configurations for transformers. These coils, also known as windings, are fundamental to a transformer's ability to step up or step down voltage. The machine ensures accuracy in the number of turns, layer formation, and tension, which are all critical for the coil's performance.

The process involves feeding wire from a spool onto a rotating former or bobbin, with careful control over tension and wire placement. Depending on the transformer's design, coils can be wound in multiple layers, side-by-side, or in more complex patterns.

How does a Transformer Coil Winding Machine ensure electrical efficiency?

Precise Turn Count: Each coil requires a specific number of turns to achieve the desired voltage ratio. The machine ensures accurate counting, which directly impacts the transformer's output.

Uniform Layering: Consistent and tight layering of wires prevents voids and short circuits, which can lead to energy loss and overheating.

Optimized Winding Tension: Correct tension prevents wire stretching or loosening, ensuring a compact coil that resists deformation and vibration, both of which can degrade performance.

Reduced Copper Losses: Precise winding minimizes gaps and maximizes the use of conductive material, reducing resistance and thus copper (I²R) losses.

Improved Insulation Integrity: The machine ensures smooth winding, reducing stress on the insulation between turns and layers, which prevents dielectric breakdown and improves the transformer's lifespan and safety.

Consistent Inductance: Accurate coil geometry directly translates to consistent inductance values, crucial for the transformer to perform according to its electrical design.

In summary, a Transformer Coil Winding Machine is paramount to the quality and efficiency of transformers. Its precision in forming coils directly impacts the transformer's ability to convert electrical energy effectively, minimizing losses and ensuring reliable operation in various applications, from power grids to consumer electronics.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!