The magnetic core is arguably the most critical component in a transformer, directly impacting its efficiency and performance. Achieving an optimal core starts with precise processing of magnetic steel sheets, a task handled by the Transformer Core Cutting Machine. But how does this machine work, and why is its accuracy so vital for ensuring peak transformer core performance?

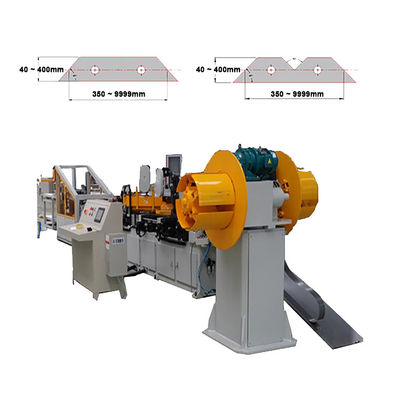

A Transformer Core Cutting Machine is a highly specialized piece of equipment used to precisely cut silicon steel sheets (also known as electrical steel or laminations) into the specific shapes and sizes required for transformer cores. These cores are typically made from thin sheets stacked together to minimize eddy current losses and improve magnetic permeability. The machine uses advanced cutting techniques, often shearing or punching, to produce various core geometries like E, I, L, or M laminations, or specific step-lap patterns for power transformers.

The accuracy of this machine is paramount for several reasons:

Minimized Core Losses: Any burrs, imperfections, or inaccurate cuts on the laminations can increase eddy current losses and hysteresis losses in the transformer core, leading to wasted energy and reduced efficiency. A precise cut ensures smooth edges and optimal magnetic path.

Optimized Magnetic Flux Path: The core's design creates a highly efficient path for magnetic flux. Accurate cutting ensures that the laminations fit together perfectly, minimizing air gaps that impede flux flow and reduce efficiency.

Reduced Noise and Vibration: Poorly cut or stacked laminations can lead to increased noise and vibration in the transformer. Precision cutting helps mitigate these issues.

Facilitates Efficient Stacking: Accurately cut laminations are easier and faster to stack, especially when using equipment like a Transformer Core Stacking Table, improving overall production efficiency.

Material Optimization: The machine is designed to cut laminations from large rolls of steel with minimal waste, optimizing material usage and reducing production costs.

Consistency and Repeatability: For mass production, the machine ensures that every lamination is identical, guaranteeing consistent core performance across all manufactured transformers.

In conclusion, a Transformer Core Cutting Machine is fundamental to building high-quality, efficient transformers. Its precision in shaping magnetic steel laminations directly contributes to reducing energy losses, improving performance, and ensuring the reliability and longevity of the transformer's magnetic core.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!