Transformer Foil Winding Machine: Enhancing Efficiency and Precision in Transformer Manufacturing

Transformer manufacturing requires precision, consistency, and high efficiency to meet the demanding standards of modern electrical equipment. Central to this process is the winding of transformer foils, a critical step that directly affects transformer performance, insulation reliability, and operational lifespan. Transformer Foil Winding Machines have emerged as essential equipment in transformer production, offering manufacturers a robust solution for high-quality, precise, and repeatable foil winding operations.

Overview of Transformer Foil Winding Machines

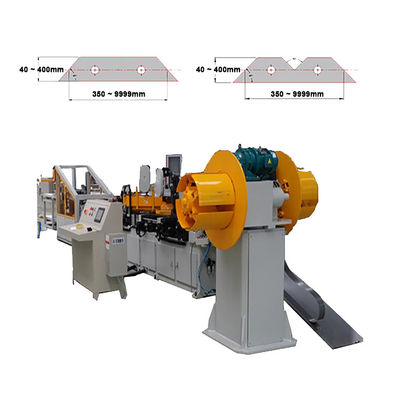

Transformer Foil Winding Machines are specialized industrial devices designed to automate the winding of metal foils used in transformer cores and windings. These machines accommodate a variety of foil types, including copper and aluminum, and are engineered to maintain precise tension, alignment, and layer consistency throughout the winding process. By providing accurate control over winding parameters, these machines help ensure that transformers meet strict electrical and mechanical specifications.

The importance of precise foil winding cannot be overstated. Improper winding can lead to uneven insulation, increased electrical losses, and reduced thermal performance. Transformer Foil Winding Machines address these challenges by combining advanced mechanical design with intelligent control systems, enabling manufacturers to achieve consistent and high-quality winding results.

Key Features and Technological Advantages

Modern Transformer Foil Winding Machines are equipped with a range of features that enhance productivity and reliability. Adjustable tension control is a critical capability, allowing engineers to maintain optimal foil tension throughout the winding process. This prevents stretching or tearing of delicate foils and ensures uniform layering, which is essential for transformer efficiency and longevity.

Automated positioning systems provide precise alignment of foil layers, minimizing human error and reducing production time. Many machines incorporate programmable winding profiles, enabling customization for different transformer specifications and sizes. This flexibility is particularly valuable for manufacturers producing both small distribution transformers and large power transformers.

In addition, some Transformer Foil Winding Machines feature integrated quality monitoring systems. These systems track foil tension, layer count, and winding speed in real-time, allowing operators to detect anomalies early and make immediate adjustments. This reduces material waste and ensures that each transformer winding meets rigorous quality standards.

Industrial Applications and Benefits

Transformer Foil Winding Machines are widely used in electrical equipment manufacturing facilities, including producers of power transformers, distribution transformers, and specialty transformers. By automating the foil winding process, manufacturers can achieve higher production efficiency, reduce labor costs, and maintain consistent product quality across large production batches.

For procurement teams and plant managers, investing in advanced Transformer Foil Winding Machines translates into measurable operational advantages. High-speed automated machines enable manufacturers to meet growing market demand while ensuring that each transformer meets performance and safety specifications. This capability is especially critical in regions with strict electrical standards and regulatory compliance requirements.

Enhancing Precision and Reducing Production Errors

One of the primary benefits of using Transformer Foil Winding Machines is the significant improvement in precision. Automated tension control and alignment systems ensure that each foil layer is wound evenly and consistently. This precision reduces the risk of electrical shorts, insulation failures, and hot spots within the transformer, enhancing overall reliability.

Moreover, by minimizing manual handling of foils, these machines reduce the potential for human error, contamination, and material damage. Consistent winding quality not only improves transformer performance but also strengthens brand reputation and customer confidence, particularly for manufacturers supplying high-voltage and mission-critical transformers.

Economic Advantages and ROI

From a financial perspective, Transformer Foil Winding Machines provide strong return on investment. Automation reduces reliance on skilled manual labor, decreases production cycle times, and lowers material wastage. The combination of increased throughput, improved quality, and reduced operational costs contributes to faster payback and higher profitability.

Additionally, the versatility of modern machines allows manufacturers to handle a wide range of transformer designs with minimal setup time. This flexibility supports production planning, reduces inventory bottlenecks, and allows companies to respond quickly to market demands, making Transformer Foil Winding Machines a strategic asset for industrial operations.

Supporting B2B Procurement and Engineering Decisions

For engineers, procurement managers, and decision-makers in the transformer manufacturing sector, selecting the right Transformer Foil Winding Machine requires careful consideration of capacity, precision, automation level, and integration capabilities. Evaluating features such as tension control, programmable winding sequences, and real-time monitoring systems ensures that the chosen machine meets both current and future production needs.

Partnering with reputable equipment manufacturers also provides access to technical support, spare parts, and maintenance services, ensuring long-term operational reliability. By aligning machine capabilities with production requirements, B2B clients can optimize their transformer manufacturing process and strengthen their competitive position in the global market.

Conclusion

Transformer Foil Winding Machines play a crucial role in modern transformer manufacturing by ensuring precision, consistency, and efficiency in foil winding operations. With advanced automation, accurate tension control, and real-time monitoring, these machines enable manufacturers to produce high-quality transformers that meet strict industry standards. For B2B clients, engineers, and procurement professionals, investing in reliable Transformer Foil Winding Machines is a strategic decision that enhances production efficiency, reduces operational costs, and supports long-term business growth in the competitive electrical equipment market.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!