In today's fast-paced manufacturing world, automation is key to achieving efficiency, precision, and consistency. For industries that rely on wound components, like transformers, inductors, and motors, the Automatic Coil Winding Machine has become indispensable. But what are the specific advantages of automating the coil winding process, and how does it benefit production?

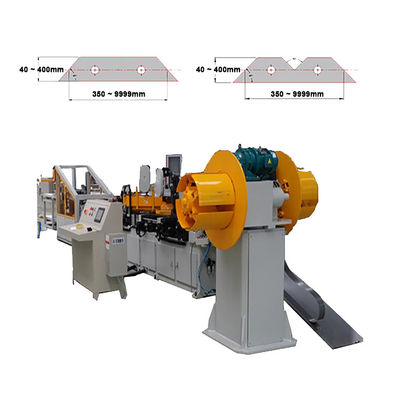

An Automatic Coil Winding Machine is an advanced piece of equipment that performs the entire coil winding process – from feeding the wire to applying insulation and sometimes even cutting – with minimal human intervention. Unlike manual or semi-automatic machines, these systems are programmed to execute complex winding patterns and precise specifications repeatedly and at high speed. This can include winding for small electronic components or larger coils for transformers, similar to those produced by a Transformer Coil Winding Machine or even a Copper Foil Winding Machine.

The advantages of an Automatic Coil Winding Machine are significant:

Unmatched Precision and Consistency: Automation eliminates human error, ensuring that every coil is wound to exact specifications, with consistent turn count, tension, and layering. This leads to higher quality and more uniform products.

Increased Production Speed: Automatic machines operate at much higher speeds than manual methods, drastically increasing throughput and meeting high-volume production demands.

Reduced Labor Costs: While there's an initial investment, automation significantly cuts down on ongoing labor expenses, leading to long-term cost savings.

Improved Efficiency: Less downtime for manual adjustments, faster cycle times, and reduced material waste contribute to overall operational efficiency.

Enhanced Safety: Automating the winding process removes operators from direct contact with moving parts and electrical components, improving workplace safety.

Complex Winding Capabilities: Automatic machines can handle intricate winding patterns and multiple taps that would be difficult or impossible to achieve consistently with manual methods.

Real-Time Monitoring and Data Collection: Many automatic systems come with integrated sensors and software that monitor the winding process, detect errors, and collect valuable production data for quality control and process optimization.

In essence, an Automatic Coil Winding Machine is a game-changer for coil manufacturing. It delivers superior quality, higher output, and significant cost savings, making it a crucial investment for any company looking to optimize its production of wound components.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!