Foil winding machgines have many advantages in transformer manufacturing, such as:

1. Enhanced Electrical Performance

Transformers produced with foil winding machines demonstrate improved electrical characteristics. The foil winding configuration provides a more linear initial voltage distribution and better impulse voltage withstand capability compared to traditional wire windings. Each layer of foil functions as a single turn, which limits interturn voltage to the plain voltage per turn rather than allowing it to accumulate as in conventional round wire windings. This significantly enhances both power frequency and impulse voltage withstand capability.

2. Improved Mechanical Stability

The foil winding process creates transformers with exceptional mechanical strength and short circuit resistance. The conductors and insulating materials are bonded together through heating, forming a compact unit that reliably withstands radial forces. The structural integrity of foil wound coils makes them less susceptible to deformation under short circuit conditions .

3. Production Efficiency and Precision

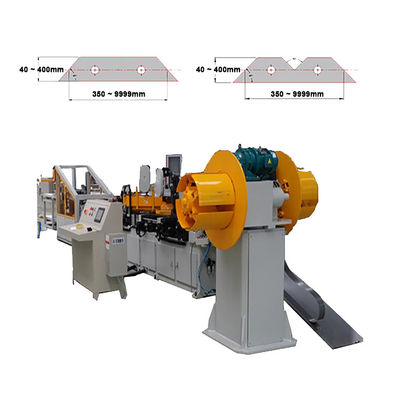

Modern foil winding machines incorporate pneumatic control systems and PLC variable frequency speed regulation technology, ensuring consistent tension throughout the winding process. The active tension control systems maintain stability during both winding and unwinding operations, preventing loose coils and ensuring uniform tightness. This automation reduces labor intensity while maintaining stable quality throughout production runs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!