Choosing a semi automatic winding machine has several compelling advantages, particularly for businesses seeking to enhance their production capabilities without the extensive investment required for fully automated systems.

A primary benefit is their cost-effectiveness. Semi automatic machines are generally more economical than automatic counterparts, making them an accessible and attractive option for small to medium-sized enterprises or processing plants operating within tighter budget constraints. This lower initial investment, coupled with substantial productivity gains over manual methods, often translates into a faster and more favorable return on investment (ROI) for companies not yet at the high-volume production scale that necessitates automation. This positions them as a strategic upgrade path for growing businesses.

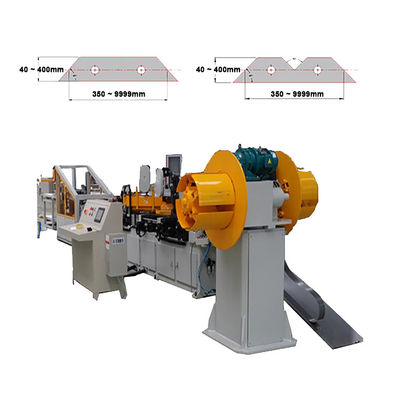

Furthermore, semi-automatic machines strike an excellent balance of control and efficiency. They significantly boost efficiency compared to purely manual winding by automating the core winding process, yet they retain essential human control for critical steps like manually fixing winding positions and removing finished coils. This hybrid approach makes them particularly well-suited for medium-sized production runs, where a degree of human oversight is still beneficial for quality assurance and flexibility. The automation of the winding process itself leads to improved productivity and reduced labor time compared to manual methods. While not achieving the absolute precision of automatic machines, semi-automatic models offer enhanced accuracy and uniformity in coil windings compared to manual operations, thereby reducing errors and improving overall product quality. Many semi-automatic machines also incorporate user-friendly features such as automatic counting, adjustable tensioning systems, and so on. These features contribute to ease of use for trained operators, streamlining the production process.

Another significant advantage is their versatility. These machines are capable of handling various winding configurations and sizes, providing considerable flexibility across different projects and product lines. This adaptability allows companies to manage diverse production needs with a single machine type. This approach also helps in bridging the skill gap in manufacturing. While automatic machines might require minimal training for operation, semi automatic machines necessitate some manual correction and compensation, meaning employees need to be adequately trained. However, this is not merely a requirement but an opportunity. It allows companies to leverage their existing skilled workforce or invest in targeted training programs, rather than needing to completely re-skill or replace their personnel with highly specialized automation technicians. This facilitates a smoother transition into automated winding, offering accessible entry points and opportunities for workforce upskilling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!