Have you ever considered the intricate process behind building a transformer, a vital component in our electrical grids? A key part of this process, especially for larger transformers, involves specialized equipment like the Transformer Foil Winding Machine. But what exactly does this machine do, and why is it so essential for creating high-performance transformers?

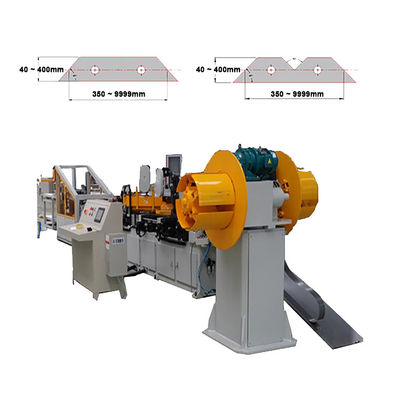

A Transformer Foil Winding Machine is a precision piece of equipment designed to wind thin strips of conductive foil, typically copper or aluminum, around a core or former to create transformer windings. Unlike traditional wire winding, foil winding is used for specific types of transformers, particularly those with high currents and low voltages, as it offers superior electrical and thermal characteristics.

The machine precisely controls the tension, alignment, and layering of the foil. It ensures that each layer is perfectly flat and tightly wound, often with interleaving insulation materials. This meticulous process is critical because even minor irregularities can lead to inefficiencies or potential failure in the final transformer.

Why is a Transformer Foil Winding Machine essential?

Improved Performance: Foil windings inherently offer better current distribution and lower eddy current losses compared to wire windings, leading to more efficient transformers.

Enhanced Thermal Management: The large surface area of foil allows for more effective heat dissipation, which is crucial for high-current applications.

Reduced Hot Spots: Uniform winding prevents localized overheating, extending the lifespan of the transformer.

Higher Current Density: Foil windings can handle higher current densities, making them suitable for powerful transformers.

Precision and Consistency: The machine ensures precise winding geometry, which is vital for meeting exact electrical specifications and ensuring repeatable quality in mass production.

Damage Prevention: It minimizes the risk of insulation damage during winding, a common issue with traditional wire-winding methods for heavy gauges.

In essence, a Transformer Foil Winding Machine is indispensable for manufacturers striving to produce high-quality, high-performance transformers. It ensures the precision and integrity of windings, which are fundamental to the efficiency, reliability, and longevity of these critical electrical components.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!