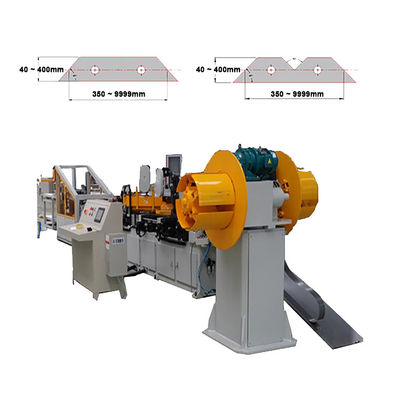

For manufacturers specializing in dry-type transformers, specialized industrial transformers, or large low-voltage (LV) windings, the traditional coil winding method using round wire is often suboptimal. The clear industry leader for these applications is the Transformer Foil Winding Machine. This equipment addresses the unique challenges of winding wide, thin conductive foil, a practice that is critical for achieving optimal electrical and thermal performance in high-current applications.

The fundamental advantage of foil winding lies in the superior electrical characteristics of the resulting coil. Unlike wire-wound coils where round wire necessitates air gaps and insulating material, foil windings create a near-perfect solid conductor path with minimal inter-turn capacitance. This is because the wide copper or aluminum foil allows for nearly 100% conductor fill factor, leading to much lower AC resistance and reduced stray losses. For high-current transformers, this translates directly to exceptional energy efficiency and significantly lower operating temperatures.

Operating a foil winding machine, however, requires mastering the challenges of handling delicate, wide material. Our machines are engineered with an advanced Edge Alignment and Tension System that is the secret to perfect foil coils. The system uses high-precision sensors to monitor both the tension across the entire width of the foil and the lateral alignment of the edge. Since even minor misalignment can create sharp edges that pierce the inter-layer insulation, our robust guiding mechanisms ensure perfect axial tracking, preventing insulation damage and short circuits.

Another critical feature is the integration of insulation management. Our machines automatically feed and cut the required width of insulating material (like Mylar or Nomex) and place it precisely between each layer of foil. This process is fully synchronized with the winding speed, maintaining perfect overlap and margin tolerances. This level of automation drastically improves quality consistency and worker safety, replacing tedious manual processes. By utilizing our Transformer Foil Winding Machine, you are not just building a coil; you are constructing a high-performance electrical component designed for the highest standards of thermal stability and long-term reliability in demanding applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!