If you've ever wondered how the essential coils inside transformers are made, you're in the right place! As a manufacturer of transformer winding machines, we're here to tell you the process and explain the technology behind creating efficient and reliable transformers.

What is a Transformer Winding Machine?

A transformer winding machine is specialized industrial equipment designed to precisely wind conductive materials, typically copper wire or aluminum wire, into coils. These coils are the fundamental components of transformers, responsible for transferring electrical energy between circuits. Our machines is used to wind this kind of coils.

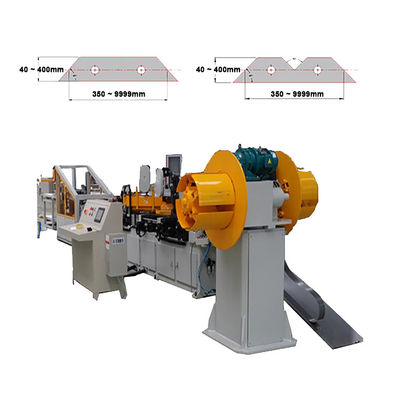

Fig 1: Semi automatic coil winding machine

Fig 2: Automatic coil winding machine

Why are Copper and Aluminum Wires Used in Transformer Coils?

Both copper wire and aluminum wire are excellent conductors of electricity, making them ideal for transformer coils.

Copper wire is widely favored due to its superior electrical conductivity, mechanical strength, and ductility. This allows for more compact designs and excellent performance, especially in higher-power applications.Aluminum wire offers a cost-effective alternative. While its conductivity is slightly lower than copper's, its lighter weight and lower price point make it an attractive option for certain transformer types and applications where weight is a significant factor.

Our machines can be used to handle both copper wire and aluminium wire, providing flexibility for various transformer designs.

How Does a Transformer Winding Machine Work?

The core function of a transformer winding machine involves carefully layering and shaping the wire around a bobbin or core according to specific design parameters. The process typically includes:

Wire Feeding: The machine draws wire from a spool.

Tension Control: Precise tension is maintained to ensure tight, uniform windings, which is crucial for the transformer's electrical characteristics.

Layering and Indexing: The wire is guided to create even, consistent layers, often with insulation material interleaved between layers to prevent short circuits.

Automated Control: Modern winding machines use advanced control systems (often CNC-based) to manage winding patterns, speed, and turns, ensuring high precision and repeatability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!